Batteries twice as powerful as those currently available may finally herald the breakthrough of electric cars. Developing such batteries is the goal of a European, DTU-led research project based on advanced materials research.

Technologically speaking, all the necessary systems for an electric car are in place—save one. This is the opinion of Poul Norby, Senior Researcher at DTU Energy, the Department of Energy Conversion and Storage.

“The only real challenge is that the battery needs to be cheaper and better. Driving an electric car is already pleasurable, and if you can increase the mileage on each charge and speed up charging, electric cars will really take off.”

Norby is the project manager of a European research project studying basic phenomena in rechargeable batteries. As early as 2017, the researchers have to submit their ideas for better—and preferably cheaper batteries. While the project is relevant for all applications of rechargeable batteries, Poul Norby finds it particularly so for electric vehicles:

“Electric cars represent a huge market. A solution viable for electric vehicles will see high sales volumes, which in turn will help drive down the price and develop the technology. Later on, it should be possible to transfer the principles to other batteries such as those that can stabilize the transfer of power from wind turbines to the electricity grid.”

|

|

|

The aim of the research project is to improve batteries so that electric cars can drive further on a single charge—and to reduce battery charging time. Photo: Joachim Rode.

|

Delighted with Tesla effect

The senior researcher points to the US company Tesla, which has combined the development of batteries for electric cars with—among other things—a home battery called ‘powerwall’:

“Technologically speaking, Tesla’s latest batteries aren’t revolutionary, but the company has managed to exploit them in a new way. At the same time, Tesla is generating a lot of attention about the importance of batteries in the society of tomorrow. I’m delighted about that.”

Currently, the dominant rechargeable batteries on the market are lithium-ion-based. Lithium is the lightest metal and it has a low reduction potential, which means that it is possible to achieve a high voltage in the smallest possible battery unit—in technical jargon—an electrochemical cell. A single cell in a lithium-ion battery can generate a maximum voltage of 4 volts. This is much higher than with other concepts. The cells are placed in series to achieve the desired voltage, which is typically higher than 200 volts in electric cars. The higher the voltage in the individual cell, the fewer cells needed, and the cheaper and lighter the final battery.

Theoretically, it is possible to increase the voltage of a lithium-ion battery cell to about 5 volts—in other words, by a significant margin.

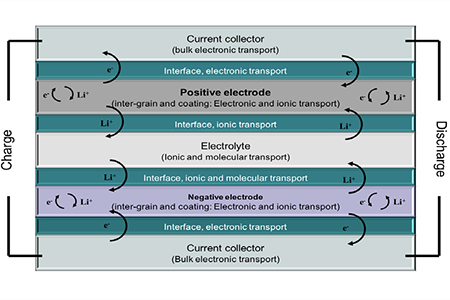

The battery as a series of interfaces

|

|

The researchers’ graphic representation of the interfaces between the battery’s key elements and the processes taking place between these interfaces. Among others, it is precisely these processes the researchers are working to improve. Illustration: Poul Norby

|

Studying the battery’s key elements

“If we succeed in significantly improving the batteries, it will be enough to secure a major breakthrough for electric cars,” says Poul Norby, adding that this is easier said than done.

“The big difference between lithium-ion batteries and the previous concepts for rechargeable batteries is that the electrolyte—that is to say, the medium through which the ions move during charging or discharge—is organic. On the one hand, this is good news because the organic electrolytes allow you to use higher voltages. On the other hand, there is an increased risk of adverse reactions, which at best means that the battery simply dies—or at worst that it causes a fire or other type of safety hazard.The higher the voltage and the more energy in the system, the greater the risk of adverse reactions. We are therefore focusing on how to keep the system stable when increasing the voltage level in lithium-ion batteries,” explains Poul Norby.

Among other things, it is interesting to see what happens in the interfaces between key elements of a battery—for example, between the positive pole (the cathode) and the electrolyte or between the negative pole (anode) and the electrolyte. In the best batteries, special conditions occur in the interfaces, thus protecting against degradation of the material. The researchers hope to find a way to improve the processes further—or at the very least ensure that the positive properties are retained—even when the voltage level is increased.

Charging time is psychologically important

The European project is called Hi-C, where 'Hi' stands for High, while the ‘C’ is the unit representing how quickly you can draw power from a battery. 1 C is the power of a full discharge of a battery in the course of an hour. Among other things, researchers are studying processes in the batteries as they occur. This can be done using powerful X-ray sources known as synchrotrons. Several other techniques are also being used, among them electron microscopy and computer modelling.

“We are optimistic about finding ways of making lithium-ion batteries more efficient without compromising safety,” says Poul Norby.

The researchers, however, are also interested in completely different types of batteries—specifically other lithium battery concepts including lithium-sulphur and lithium-air—as well as other materials.

The aim is clear. The batteries must be twice as powerful as those currently available, thus enabling motorists to cover similar distances in the electric cars as they do in conventional vehicles. It would also be good if charging could be speeded up, says Poul Norby:

“In reality, lithium-ion batteries are already very quick to recharge. The fact that charging time is still perceived as a barrier, is probably more psychological than anything. Drivers are used to filling up quickly at petrol stations. Fortunately, there is a good chance that we can find ways to charge the batteries even faster.”

Video of PhD Jonathan Højberg's work with litihum-air-batteries i collaboration with Haldor Topsøe A/S