New buildings are often a cause for celebration, but there is not much to celebrate when looking at the climate footprint of the construction industry, which is among the world’s highest.

In 2021 alone, 2.9 billion tonnes of CO2 was emitted throgh the industry’s cement production, corresponding to more than seven per cent of the total global CO2 emissions. The emissions occur when the cement is heated, as the high temperatures cause CO2 release.

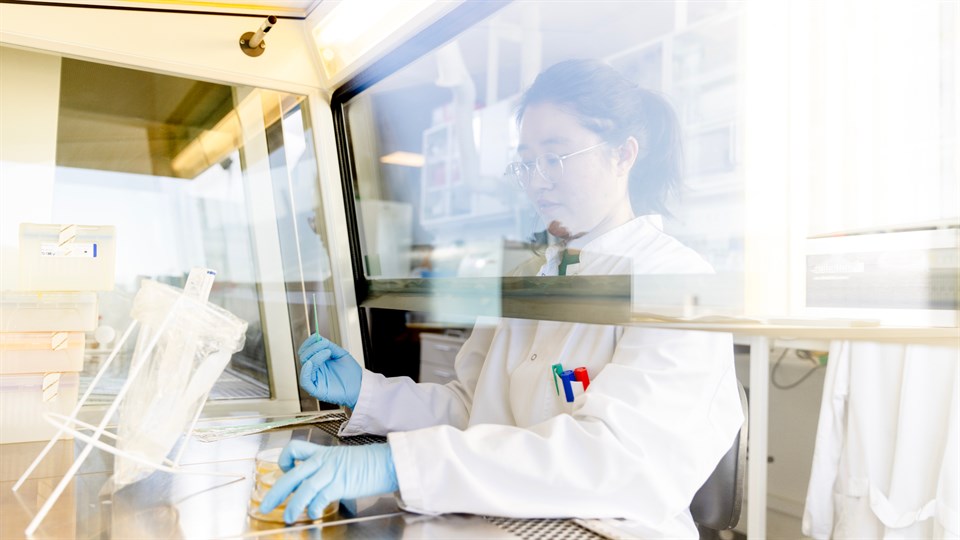

Postdoc Colleen Varaidzo Manyumwa and PhD student Chenxi Zhang are working on solving this problem - initially at a micro level. By transferring genes from microorganisms to a particularly tough kind of bacteria, they have succeeded in getting the bacteria to produce an enzyme with a highly sought-after property. The enzyme can quickly and efficiently bind CO2 to limestone, or calcium carbonate, which is one of the main ingredients in cement.

“The process is seen in nature, where ocean corals also capture CO2, but it can take centuries. With our enzyme, it only takes a few minutes,” says Colleen Manyumwa.

The researchers are now working to make the production of the enzyme even more efficient, so their solution can eventually be scaled up and implemented in the industry. The goal is for the cement factories to have a bioreactor with the specially designed bacteria, also called a cell factory, to ensure that the CO2 emitted is captured rather than leaking into the atmosphere.

“It will work a bit like a green circle: The factory releases CO2 during heating, we capture it in the bioreactor which binds the CO2 to calcium carbonate, the factory then reheats the calcium carbonate to make new cement, and once again we capture the CO2 released,” says Chenxi Zhang.

How the researchers’ cell factory works at the cement factory: