The first attempt exceeded the 39-minute time limit. The second ended in mechanical failure. But on their third try, the DTU students behind the ‘red lightning’ eco road car Dynamo set a new world record in the Urban Concept class in the Shell Eco-marathon Europe in Rotterdam in May 2013.

After the mandatory ten laps, the car had used so little bioethanol that its fuel consumption equated to 612.3 kilometres on a single litre of petrol. The closest rivals from Luleå Technical University in Sweden managed only 287 kilometres per litre.

DTU Roadrunners is a student-run project. The DTU students on the course designed and developed the technology since the course—which cuts across study programmes—began in autumn 2012.

Calculating consumption

The cars do ten laps on a closed circuit—a total of 16.3 kilometres—to be completed in under 39 minutes. Officials then measure fuel consumption. The consumption of second generation bioethanol–which fuels Dynamo—is converted into joules for ethanol, as ethanol has a lower energy content than petrol—and then into joules for petrol.

Finally, a calculation is made for the number of kilometres driven on one litre of petrol. 39.4 mg ethanol corresponds to 612.3 kilometres on one litre of petrol.

Breakdown of the amazing DYNAMO

|

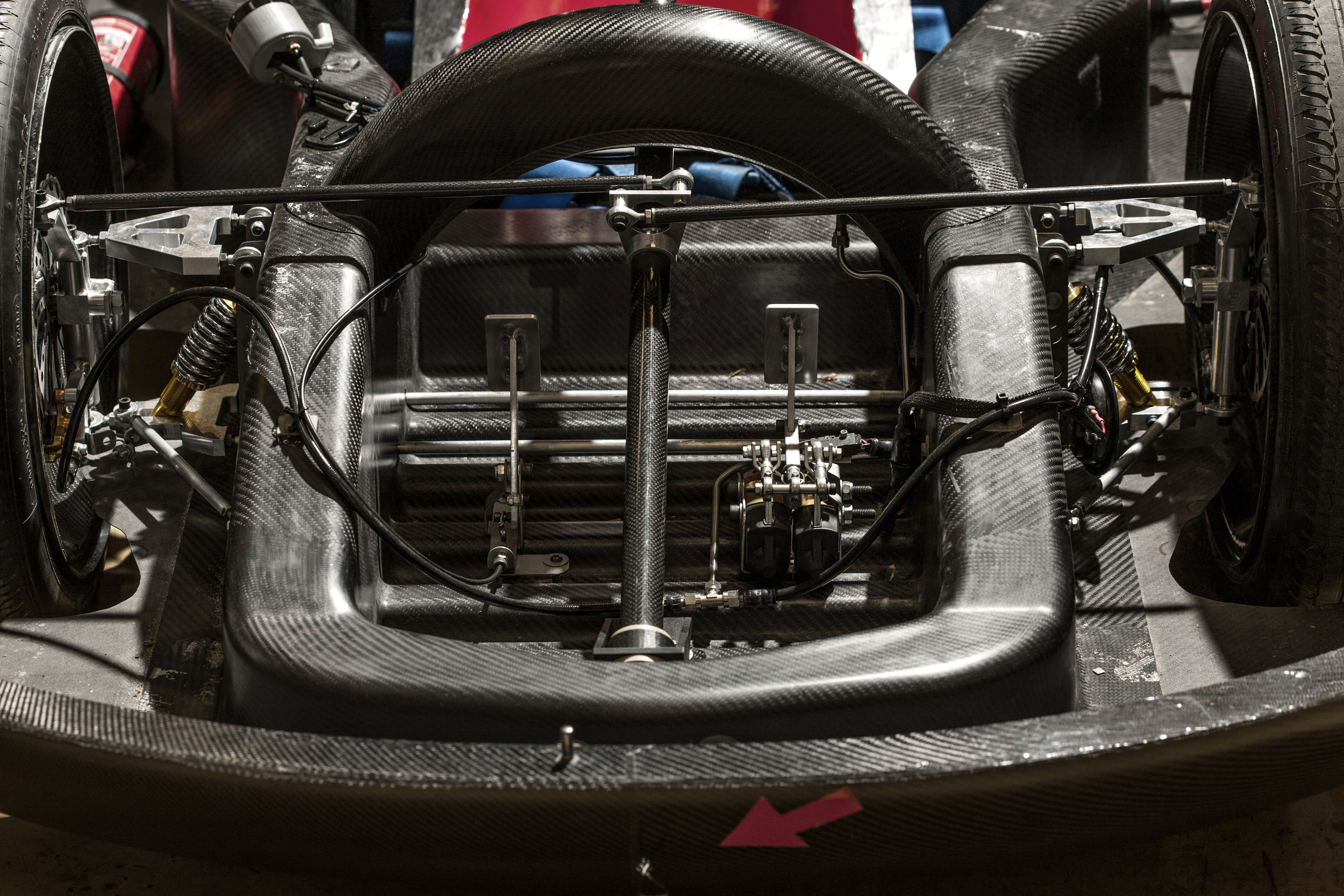

Lightweight carbon fibre chassis

The new carbon fibre chassis weighs 20 kg or only half the weight of the chassis used last year. The lighter weight was achieved using a more intelligent design of the supporting construction. The car weighs 108 kg without the driver. In 2012, the corresponding weight was 136 kg.

|

|

|

Carbon fibre rims and hubs save weight

For the first time ever, the cars four wheel rims are made of carbon fibre, achieving a savings of 6 kg compared with the year before. The hubs are made of anodized aluminium. The hub caps are 3D printed in ABS plastic at DTU’s Fablab.

|

|

|

Brakes reutilize energy

The battery for the car’s new KERS system (Kinetic Energy Recovery System) helps to reuse energy under braking. The recovered energy is stored in the battery for later use under acceleration with the electric motor—before the combustion engine takes over. The energy is stored in the so-called supercapacitors located at the base of the system.

|

|

|

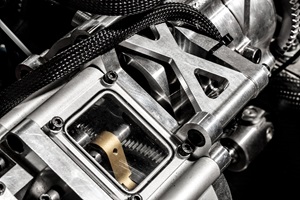

Low-friction engine

This year, the car’s moped engine and driving line have been given a lighter and more compact crankcase that enables full declutching of the starter motor when not in use. This reduces weight and friction on the driving line, enabling the car to drive further on a litre of fuel.

|

|

|

Steering wheel 3D printed at DTU

The steering wheel is 3D printed and equipped with an info screen and buttons that control electrics such as lights, horn and starter motor. The driver now receives information via the steering wheel display and can control the car’s functions from here. Several other components have been 3D printed—the majority on DTU’s own Fablab printers.

|

|

|

Aerodynamic bodywork

The car’s outer shell is extremely aerodynamic, which in turn reduces fuel consumption. The design was developed according to advanced calculations and tests of how best to reduce the car’s wind resistance under driving conditions. The car’s Plexiglas window section is completely new and glued on.

|

|