17 March 2015 was a landmark date in bridge building history when a new bridge over Vorgod stream in Central Jutland was erected in the course of a single morning. This was possible because the bridge was not cast on site, but rather arrived in a kind of assembly kit comprising concrete decks clamped together with wires like pearls on a string.

The arch structure is one of the best ways of transferring forces and therefore ideally suited to bridges. However, arch bridges made of concrete are traditionally expensive and time-consuming to build, as they are cast on-site across several costly wooden structures. The so-called pearl-chain technology solves this problem, employing instead mass-produced, super-light concrete decks held together with steel wires.

|

Due to the special construction, the bridge can be hoisted into place in one piece.This saves time and resources.

|

|

|

Technology behind the bridge

The technology is based on several patented ideas generated by Professor Kristian Hertz from DTU Civil Engineering in the spin-out company Abeo. One of the ideas is the super-light concrete deck called the SL-Deck, which is a unique combination of strong and lightweight concrete. In cross-section, it looks like concrete waves that have been fused together.

A traditional concrete structure uses solid stone reinforced with iron to prevent cracking. In addition to being heavy, it is impossible to determine exactly where in the structure the forces are located. The idea behind SL-Deck is that you place the strong concrete exactly where you want the forces and use lightweight concrete to fill out and stabilize the structure.

SL-Deck-elements are used in houses to separate floors, where they also have proved extremely effective in meeting sound and fire protection requirements. And now they also feature in a new wing at a Danish high school and a new residential complex in Copenhagen.

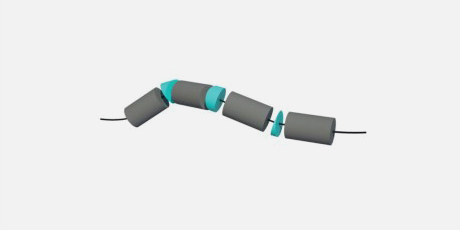

But the technology is even more revolutionary when the mass-produced, super-light decks are used in an arch bridge. Here, the ends are cut diagonally to create the arch shape. A distortion wire is then pulled through a tin rod inserted into the concrete deck. When the wire is tightened, the decks form a stable arch capable of supporting the forces as soon as the arch is hoisted into place.

|

Bridge elements are made of light-weight concrete consisting of a mix of both strong and light-weight concrete

|

|

|

The pearl-chain bridge principle is simple: cement pearls are threaded along a steel wire, which is then tightened.

|

|

|

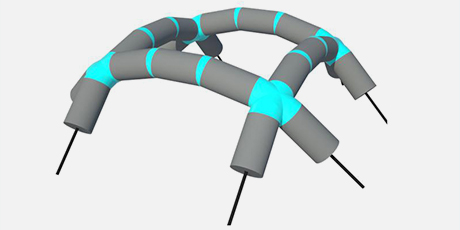

The pearl-chain principle can be used in many different shapes and structures.

|

|

The complete pearl-chain bridge can be lifted into place in the course of a few hours. Traffic under the bridge can then resume while the bridge is finished with a layer of stabilizing fill and a final road surfacing. This saves both time and money, of course.

Modern twist on ancient design

Dating back at least 6,000 years, the technique of building arch bridges was practised by the Sumerians, the Egyptians, and later by the Chinese. The Romans learned the art from the Etruscans, perfecting it to such an extent that a surprising number of these bridges are still standing to this day and are used by modern heavy vehicles. This fascinates Kristian Hertz, who travels as often as possible to study the designs. The pearl-chain bridge is his personal refinement of the classic construction.

Although the arch is by its very nature strong and durable, it has always suffered from the problem of sustaining concentrated load imbalances at the so-called forward quarter point, says Kristian Hertz. However, he and his fellow researchers have also found a solution to this problem:

"It is important that engineers learn to be bold and innovative. They must be able to perform accurate calculations for new constructions and vouch for their strength and durability."

Professor Kristian Hertz, DTU Civil Engineering

“In a joint PhD project with the University of Iowa, we have developed a filler we call drainage concrete because you can simply pour water directly through it. When the road surface is laid on the bridge, you still have to fill up with gravel, but by using drainage concrete instead, we can direct the forces up through the filling material to a top plate. Consequently, we end up with what we call a sandwich arch, which largely solves the problem of misaligned load.”

Pearl-chain bridges of various lengths have, of course, been tested at the element factory—among other things to determine how much load they can withstand. It was only when subjected to a 98.8 tonne load—or three to four times the maximum permissible load at the critical forward quarter point—that the 220 mm thick arch gave way.

“Even the breach was pretty cool. Cracks in the cement gave a forewarning of what was to come and the actual breach was a relatively calm affair with no exploding fragments,” explains Kristian Hertz, emphasizing that there is significant safety built into the process.

From idea to reality

The first real pearl-chain bridge consisting of 12 arches was hoisted into place over Vorgod stream in the space of five hours. Abeo has also developed a new design for pearl-chain bridges in collaboration with Henning Larsen Architects. Prototypes of the super-light structures are also a feature of DTU’s building 324, where 400 m2 indoor walkways connect six separate building elements on two levels.

|

It took five hours to build a new arch bridge across Vorgod stream. With traditional construction methods it would have taken several days

|

|

. .

|

In the classroom, Kristian Hertz encourages his students to play with the technology and calculate how far it can be stretched. Some, for example, imagine a bridge with a shopping arcade with shops on two floors spanning the Thames. Others are working on a Kattegat Link between Zealand and Jutland via Samsø using 100-metre arches.

“It is important that engineers learn to be bold and innovative. They must be able to perform accurate calculations for new constructions and vouch for their strength and durability. Unfortunately, there is a certain reluctance towards the new technology among established engineers, but now that we have built the first five or six houses and a bridge with the SL-Deck and pearl-chain technology, we hope that many more engineers—also in other countries—will give it a go,” says Kristian Hertz.

Article from DYNAMO no. 42, DTU's quarterly magazine in Danish.